Introduction - Concrete Mix

For the small scale construction, we does-not have the availability of batching plants, there are two types of methods which are followed for the mixing purpose of concrete, they are

(i) Weight Batching

(ii) Volume Batching

On the above two, the weight batching is done by calculating the weight of the materials required for the concrete mix which is the most appropriate method, which we are going to look at in this article.

On the other side, the volume batching is done by pouring the materials inside the pre-fabricated molds/gauges or farma’s (Hindi). The method is not considered must appropriate since, there are chances of pores, bulging, etc of the aggregate and sand, due to which volume may get increased but the desired ratio of the mix cannot be achieved.

This calculation method is preferred mostly to the Nominal mix of the concrete, which is from grade M5 to M25 mix.

Important units for calculation - Concrete Mix

Shrinkage Factor / Factor of Safety | 1.54 - 1.57 |

Density of Cement | 1440 kg/m3 |

Density of Sand | 1600 kg/m3 - 1800 kg/m3 |

Density of Aggregate | 1500 kg/m3 - 1850 kg/m3 |

Water to Cement Ratio (w/c) | 0.50 (assuming) |

Concrete Mix | M20 (assuming) |

M20 mix grade | 1:1.5.3 ( IS 456) |

Calculation - Concrete Mix

Finding out the quantity of Cement, Sand, Aggregate in 1m3 Concrete

We are going to calculate the weight of materials from the M20 grade of concrete, where M is referred to as mix and 20 is the compressive strength at N/mm2.

The Ratio of M20 grade concrete is = 1:1.5:3

Where,

1 part is cement, 1.5 part is sand and 3 parts is aggregate.

Here, while calculating for 1m3 of concrete, we use to multiply the quantity with the value ranging between 1.54 to 1.57 as a factor of safety or shrinkage factor of the concrete.

This is done since the volume of the dry concrete is different compared with wet concrete. More easily, we can say, while pouring concrete the concrete which we use be wet in nature but once it starts hardening, the concrete start showing shrinkage behavior in it making in the reduction of the volume of concrete.

To overcome the problem we take the factor of safety or the shrinkage factor.

Note - Lower grades between M5 - M 15, the shrinkage factor tends to be lower than 1.54. This is because of the low workability of the concrete. The less water in the concrete, the lower shrinkage will be seen.

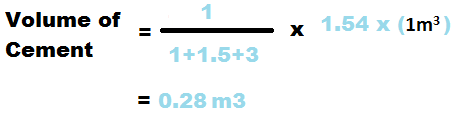

1. Calculating the weight of cement in 1m3 concrete mix

We know the density of cement is 1440 kg/m3.

Therefore, to calculate the weight of the cement we have to multiply the volume calculated by the density

(Mass= Volume x density)

Mass of cement = 0.28 x 1440

= 403.2 Kg cement

Since a bag of cement is 50 kg, we require around 8 bags of cement for 1m3 concrete.

2. Calculating the weight of sand in 1m3 concrete mix

From the above calculation, we have received the volume of the sand in the concrete mix, To convert it to the weight again we have to multiply the volume with the density of sand where we assumed the density of sand 1800 kg/m3

Mass of Sand = 0.42 x 1800 kg/m3

= 756 Kg’s

3. Calculating the weight of aggregate in 1m3 concrete mix

Same procedure as above we will follow, the volume must be multiplied with the density of aggregate to find the weight of aggregate

Mass of aggregate = 0.84 x 1850 kg/m3

= 1554 kg's

So, from this we can say for 1m3 of concrete we will require 1554 kg of aggregate.

No comments:

Post a Comment