Brick Kiln

Introduction of Brick Kiln

Brick Kiln is an ancient technology, who's traditional method (Firing Technique) is still being practiced in countries like India, Pakistan, Bangladesh etc. The kiln technique has been improvised in developing countries years after years.

The kiln technique is determined in two processes under which the brick are been prepared such as

- Intermittent (Traditional method/Periodic kind of kilns)

- Continuous (Mostly preferred in developed countries)

After China, India is the second largest manufacturer of bricks, producing over 10 percent of the global production.

Classification of Brick Kilns

|

| Classification of Brick Kilns |

Brick are been prepared in two ways Intermittent (Traditional method/periodic kind of kilns) and Continuous (Mostly preferred in developed countries)

Firstly we will learn about the traditional method

Intermittent (Traditional method/Periodic kind of kilns)

They are known as periodic kilns because only one process can be carried out at a time. In this method the bricks the fired in batches inside the kiln. The kiln is been sealed from outside, than the kiln is been heated up as per the schedule. Once the firing of cake is done, the kiln and the bricks are left to cool down. The bricks are been removed once the kiln is cool down properly. For the next cycle the Kiln is properly cleaned.

Now, the intermittent Kilns are further classified into

1)Kilns without chimneys

They are the oldest and most traditional and still been practiced in many countries. This kiln is highly polluting, inefficient fuel use and labour intensive. Clamp firing is of many sizes depending on number of bricks to be fired at once. They are kept side by side to coal or fuel material for burning and space is kept between them for passing of air. Clamp firing has two variants which are

- Scove Kilns - Wall of the camps are plastered from outside for more efficiency

- Scotch Kilns- When clamp is surrounded by four walls.

2) Kilns with chimneys

- Up-draft kilns- In the up-draught kilns the flame is introduced from the bottom and is been exhausted out from the top. they consists of 3 components Fire box (where flame enters), Damper (which controls exhaust at top), Stack area (where bricks are placed).

|

| Up-draft kiln |

- Downdraft Kilns- They are designed in such a manner that the heat and air can circulate through the kiln

|

| Downdraft Kilns |

- Climbing Fire Kiln- These kilns are long chambers and often close to updraught air flow, they are built on a slope which itself acts as a natural chimney, enhancing the kiln's draw.

Continuous Kilns

The continuous Kilns is been carried out in two process such as moving fire Kiln in which Bricks remain stationary and the fire moves through the kiln with the assistance or help of a chimney or suction and the other is, moving ware kiln in which bricks are moved through a stationary fire zone.

Moving fire Kiln

- Hoffman Kiln - They are designed with large, permanent masonry arches and expensive tall chimney approx. 30 metres tall. Two parallel tunnels are build side by side consist of a curve tunnel at either side. Chimneys are constructed outside and can be connected to more than 1 kiln.

Minimum - 16 chambers.

Efficient- 22 chambers.

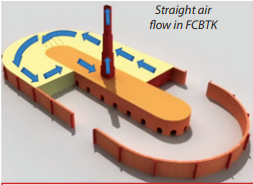

- Fixed Chimney Bull’s Trench Kiln (FCBTK)- The technology is most widely used in South Asian countries such as (India, Bangladesh, Pakistan and Nepal) , In this the fire is always burning and the circulation of air is always to the direction of the air flow connected to chimney which is considered as straight path. Inside all the process can take place simultaneously such as heating, cooling etc. FCBTK has a tall, expensive 30 meter brick chimney and is highly polluting. they are operated in dry seasons mostly and been operated continuously since fire is always burning inside it.

|

| Fixed Chimney Bull’s Trench Kiln (FCBTK) |

- Zig-Zag kilns- They are very similar to Fixed Chimney Bull’s Trench Kiln, the difference between both of them is the air flow path which happens in zig-zag manner in this kiln. In this the fire moves in the closed rectangular room and the bricks are arranged in such a manner that fir moves in zig-zag way. The power coal is fed in small quantities in zig-zag kiln and the fuel feeding zone is six times longer than that of FCBTK which results in improved combustion and heat transfer rate and uniform temperature across the kiln cross section.

|

| Zig-Zag kiln |

Moving ware Kiln

- Tunnel Kiln- This is a highly mechanized and automated process. These kilns are expensive to construct and required high skilled workers.These kilns are very long and only the central part is heated, the bricks are been transported from the entrance and as the bricks reaches the central part, the central area is more heated observed compare to entrance.

No comments:

Post a Comment